Body Builder Connectors and Lighting Interface

3/29/2019

Quick Reference Guide for Body Builder Connectors, Pinouts, Mating Connector Housing Assembly and Terminal Part Numbers. Also end of frame Lighting Connector information provided.

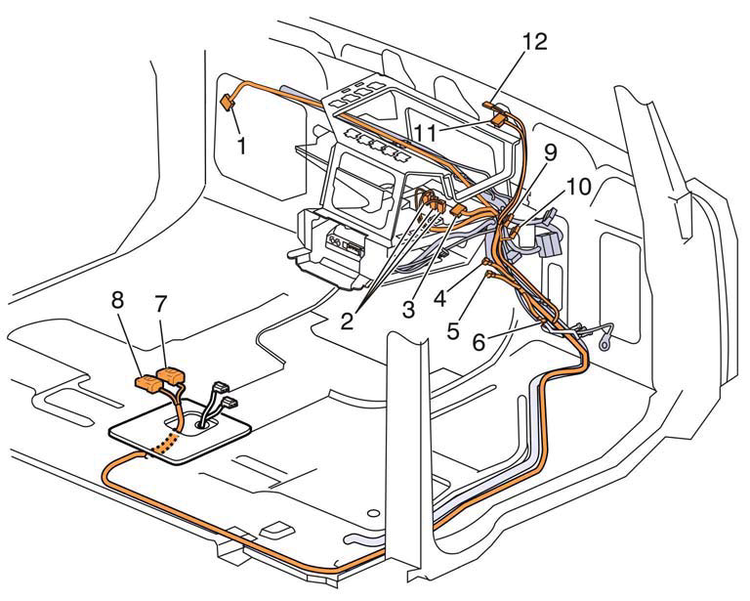

Body Builder Harness

Body Builder Harness with Auxiliary Switch Overlay (Dash), VN

W3035627

- Dual power take off (PTO), Switch

- Body Builder Module (BBM) Electronic Control Unit (ECU)

- Splice Pack (5K141B)

- Main Cab (OPT5)

- Main Cab (OPT1587)

- Main Cab (MCBB)

- Body Builder Connector # 4 (203D.A)

- Body Builder Connector # 3 (203C.A)

- Body Builder Connector # 3 (203C)

- Body Builder Connector # 4 (203D)

- Terminating Resistor (R08A)

- Overlay Options (OPT3)

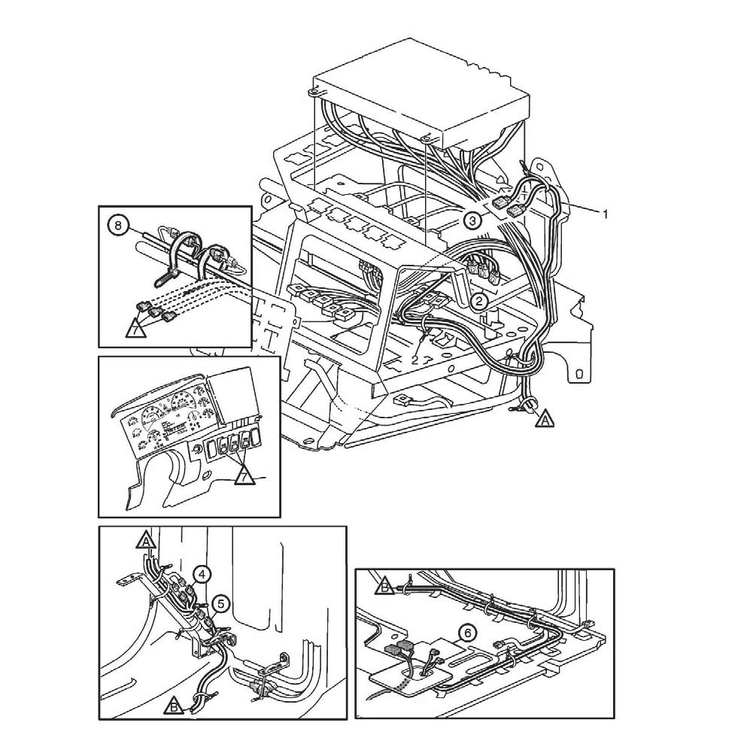

Body Builder Harness with Auxiliary Switch Overlay (Dash), VHD

W3118564

- Wiring Harness

- BB Module

- Datalink Option Connector

- Datalink Connection

- Body Builder Module Connection

- Body Builder Module Connection

- Auxiliary Switch Connectors

- To 141A Splice

Body Builder Connections End of Frame

Body Builder connections end of frame provides access to the electrical lighting connections. The circuits provide for separate STOP and TURN signals.

Notes:

- Mating connectors are located in the cab when the truck is delivered.

- If a combined Stop/Turn is required, use the in-line connection point in the rear lighting in-line connector.

W3118341

Fig. 1 Connectors located at the end of frame

The connections are grouped into three connectors:

| 3-Way Metri-Pack 480 Series Connector | ||

| Cavity Assignment | Wire Color | Description |

| 1 | Black | Trailer Marker/Clearance lamps |

| 2 | Brown | Trailer Tail lamps |

| 3 | Red | Stop Lights |

W3118342

| 3-Way Metri-Pack 630 Series Connector | ||

| Cavity Assignment | Wire Color | Description |

| A | Yellow | LH Turn Signal Light |

| B | Green | RH Turn Signal Light |

| C | Blue | Auxiliary (12V ignition power) |

W3118343

| 1-Way Maxi Connector | ||

| Cavity Assignment | Wire Color | Description |

| A | White | Ground |

W3118344

Body Builder Pass Through Connectors (VHD)

Three body builder option connectors are in the cab and engine harnesses. These wires provide a pass-through for add-on wiring from the engine compartment to inside the cab.

They are single wires, with plugged connectors, circuit numbers 999A, 999B, and 999C. They are located near the engine pass-through on the engine side, and inside the dash, behind the instrument cluster, on the cab side.

Note: A body builder connector is installed with 14 wires for passing circuits through the cab floor.

W8003318

Option Connectors, Driver Side Engine Compartment

W3118565

Body Builder Connector

VHD Body Builder Connectors

Connector Usage/Gender Information

| Connector/Item | Connector Series | Gender On-Vehicle |

| BB Connector #1 (ELCE-PK) | 280-GT, Unsealed 16-way | Female Housing/Female Terminals |

| BB Connector #2 (ELCE-PK) | 280-GT, Unsealed 16-way | Male Housing/Male Terminals |

| BB Connector #3 (ELCE-CK) | 150-GT, Unsealed 16-way | Female Housing/Female Terminals |

| BB Connector #4 (ELCE-CK) | 150-GT, Unsealed 16-way | Male Housing/Male Terminals |

| Snow Plow Prep. | 280-GT, Sealed 10-way | Male Housing/Male Terminals |

|

Cable kit 85148537 is for connectors 1 and 2. Cable kit 85146080 is for connectors 3 and 4. |

Delphi/Packard 150-GT, Unsealed 16-way

Female Housing/Female Terminals

W9000766

| Item | Supplier P/N | VOLVO P/N |

| Housing | 15332177 | 20481359 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) |

12191811 12191812 |

N/A N/A |

| Cable Seals-Not Required | ||

| Cavity Plugs-Not Required |

Male Housing/Male Terminals

W9000767

| Item | Supplier P/N | VOLVO P/N |

| Housing | 15332182 | 20481361 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) |

15304701 15304702 |

N/A N/A |

| Cable Seals-Not Required | ||

| Cavity Plugs-Not Required |

Delphi/Packard 280-GT, Sealed 10-way

Female Housing/Female Terminals

W9000768

| Item | Supplier P/N | VOLVO P/N |

| Housing | 5326660 | 20478205 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) 1.50-3.00 mm² (0.059-0.118 in²) |

15304718 15304719 15304720 |

N/A N/A N/A |

| Cable Seals-choose by insulation O.D. | ||

|

1.85-2.25 mm² (0.072-0.088 in²) 2.50-3.20 mm² (0.098-0.125 in²) 3.40-3.90 mm² (0.133-0.153 in²) |

15366066 15366067 12191235 |

N/A N/A N/A |

| Cavity Plugs | 15305170 | N/A |

Male Housing/Male Terminals

W9000769

| Item | Supplier P/N | VOLVO P/N |

| Housing | 15326661 | 20478204 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) 1.50-3.00 mm² (0.059-0.118 in²) |

15304730 15304731 15304732 |

N/A N/A N/A |

| Cable Seals-choose by insulation O.D. | ||

|

1.85-2.25 mm² (0.072-0.088 in²) 2.50-3.20 mm² (0.098-0.125 in²) 3.40-3.90 mm² (0.133-0.153 in²) |

15366066 15366067 12191235 |

N/A N/A N/A |

| Cavity Plugs | 15305170 | N/A |

Delphi/Packard 280-GT, Unsealed 16-way

Female Housing/Female Terminals

W9000770

| Item | Supplier P/N | VOLVO P/N |

| Housing | 15326952 | 20378995 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) 4.00-5.00 mm² (0.157-0.196 in²) |

15304711 15304712 15304713 |

N/A N/A N/A |

| Cable Seals-Not Required | ||

| Cavity Plugs-Not Required |

Male Housing/Male Terminals

W9000771

| Item | Supplier P/N | VOLVO P/N |

| Housing | 15326956 | 3186494 |

| Terminals-choose by conductor size: | ||

|

0.35–0.50 mm² (0.013-0.019 in²) 0.75–1.00 mm² (0.029-0.039 in²) 4.00-5.00 mm² (0.157-0.196 in²) |

15304723 15304724 15304725 |

N/A N/A N/A |

| Cable Seals-Not Required | ||

| Cavity Plugs-Not Required |

Basic Prep Kit

“Basic” Prep Kit - ELCE-PK (Sales Code: L3–A1)

The basic prep package installed in all VHDs prewires for the most commonly used body builder circuits. It includes fused battery power circuits (both switched and unswitched), ground, Reverse power, and access to the 'stalk' PTO engine speed adjustment circuits.

A 31-way pass through connector in the cab floor is included for passing circuits from inside to outside the cab in a safe, weather-proof manner. In addition, there are two unassigned circuits (MAAA1 and MAAB1) installed in the 102-way pass through from the cab to the engine compartment for body builder use.

If the vehicle is equipped with an Allison Transmission, additional Allison-specific circuits are pre-wired to the body builder connector, as well.

The following tables list the pinout and mating connector information for the 16-way body builder connectors which are part of the ELCE-PK package, located on the cab floor between the seats.

Description of Circuits included in ELCE-PK (Basic Prep Kit)

This is the 'basic' prep kit; Available with all engines. Content is the same for all engines, but differs depending on transmission.

Note: Verify fuse numbers and values with the fuse legend decal installed in your particular vehicle.

Connector #1

Type: 16-way, unsealed Packard GT 280-series (female housing w/ female terminals)

Location: Between driver and passenger seat

Present: Always present with ELCE-PK option (sales code L3-A1)

| Pin | Circuit Gen 2 2018 | Circuit Gen 1 Pre 2018 | Description | Notes |

| A | X03DH3 | X03EA2 | Body Builder Ground Return | 30A Max. |

| B | HA10AB | MABA1 | Alternator “R” Terminal | N/A |

| C | F19A1 | F43A2 | Fused, Unswitched Battery Power | 30A “Body Builder” Maxi Fuse; 25A Max. |

| D | F35A1 | F65A1 | Fused, Ignition Switched Power | 15A “IGN-X” fuse; draw 12A Max. |

| E | N122A1 | N122A1 | Allison Defined | N/A |

| F | N123A1 | N123A1 |

Varies; typically Reduced Eng Load at Stop Input |

Typ. Reduced Engine Load at Stop Input |

| G | F49A4 | F62F2 | +12V when transmission in REVERSE |

Fed via “Body Builder Reverse” fuse; 5A Max. |

| H | F47A1 | F64A1 | Fused, Ignition-Switched Power | 15A “IGN-Y” fuse; draw 12A Max. |

| J | F46A1 | F29A1 | Fused, Ignition-Switched Power | 15A “IGN-Z” fuse; draw 12A Max. |

| K | CAKJ5C5 | MAKA1 | Stalk PTO engine speed increase | Active High Input |

| L | CALJ5F5 | MALA1 | Stalk PTO engine speed decrease | Active High Input |

| M | F65A3 | F34C3 | Remote PTO1 Output | Active High Output; 4A Max. |

| N | CA1AN | F34E3 | Remote PTO1 Input/Activation | Active High Input |

| P | N/A | N/A | Empty | |

| R | N/A | N/A | Empty | |

| S | N/A | N/A | Empty |

Connector #2

Type: 16-way, unsealed Packard GT 280-series (male housing w/ male terminals)

Location: Between driver and passenger seat

Present: Present with ELCE-PK option (only when Allison transmission installed)

| Pin | Circuit Gen 2 2018 | Circuit Gen 1 Pre 2018 | Description | Notes |

| A | N/A | N/A | Empty | |

| B | FR15A87A | NABA1 | N.C. contact of relay controlled by A112 | Typical PTO Enable Output |

| C | FR15A87 | NACA1 | N.C. contact of relay controlled by A112 | |

| D | FR15A30 | NADA1 | COM contact of relay controlled by A112 | |

| E | FR16A87 | NAEA1 | N.O. contact of relay controlled by A114 | Typical Neutral Indicator for PTO |

| F | FR16A87A | NAFA1 | N.C. contact of relay controlled by A114 | |

| G | FR16A30 | NAGA1 | COM contact of relay controlled by A114 | |

| H | N103A2 | N103A2 | Switch Return (Ground) |

Use for all Allison-connected active low inputs |

| J | N117A2 | N117A2 | Allison defined | Typically AutoNeutral Input |

| K | N143A1 | N143A1 | Allison defined | Typically PTO Enable Input |

| L | XO3BA | XO3BA | Allison ECU Power Ground | Use for ground-connected Allison Outputs |

| M | N142A1 | N142A1 | Allison defined | Typically Range Hold Input |

| N | N101A1 | N101A1 | Allison defined | Typically Range Inhibit Input |

| P | N125A1 | N125A1 | Allison defined | Typically Speedometer Output |

| R | N113A1 | N113A1 | Allison defined | Output; varies by application |

| S | N105A1 | N105A1 | Allison defined | Typically 'Speed Indicator A' Output |

| 1 The function of all Allison-defined circuits (Axxx) will depend on the chosen Vocational Package. Always refer to Allison Documentation for details. | ||||

Note: Allison-Only Circuits numbered "Axxx": Refer to Allison Transmission documentation or Body Builder Transmission service bulletins (using the "Axxx" circuit references) to determine the exact function of each Allison circuit, as they can vary depending upon the vocational package chosen.

Connector/Mating Part Information

Note: Unless otherwise indicated, all part numbers are Delphi / Packard:

| Connector/Item | Supplied on vehicle | Mate required to plug into vehicle |

| Connector #1 | Packard 280-GT series (unsealed), 16- way; Female housing & Terminals | Packard 280-GT series (unsealed), 16- way; Male housing & Terminals |

| Housing Assy: |

Packard PN 15326952 VOLVO PN 20378995 |

Packard PN 15326956 VOLVO PN 3186494 |

| Terminals | Female Terminals, size as required | Male Terminals: Packard 15304723 (0.75 ~ 1.00 mm²) Packard 15304724 (1.50 ~ 3.00 mm²) Packard 15304725 (4.00 ~ 5.00 mm²) |

| Connector #2 | Packard 280-GT series (unsealed), 16- way; Male housing & Terminals | Packard 280-GT series (unsealed), 16- way; Female housing & Terminals |

| Housing Assy: | Packard PN 15326956 VOLVO PN 3186494 | Packard PN 15326952 VOLVO PN 20378995 |

| Terminals: | Male Terminals, size as required | Female Terminals: Packard 15304711 (0.75 ~ 1.00 mm²) Packard 15304712 (1.50 ~ 3.00 mm²) Packard 15304713 (4.00 ~ 5.00 mm²) |

Battery and Ignition Feed circuits (F43A1, F65A1, F64A1, and F29A1)

These unswitched and ignition-switched power feeds are provided for body builder's use. Note that each circuit is fused by either a Maxifuse in the Power Module, and/or a minifuse in the standard Fuse and Relay Center. Observe the maximum current capabilities of each circuit.

Note: Verify fuse numbers and values with the fuse legend decal installed in your particular vehicle.

| Circuit | Fuse/Fuse Size | Maximum Usable Current |

| F43A1 | F43/10A/30A | 25 A (80% of fuse rating) |

| F65A1 | F65/15A | 12A |

| F64A1 | F64/15A | 12A |

| F29A1 | F29/15A | 12A |

Note: NEVER increase the size of the fuse beyond what is listed above (or on the Fuse and Relay Center decal). If needed for the application, though, the fuse size may be reduced as dictated by load of the attached equipment.

| Special NOTE for the F65A1 circuit (Fuse F65) and F64A1 circuit (Fuse F64) |

|

These circuits are in the electrical 'path' of the PLC4TRUCK signal as it makes its way from the trailer (AUX circuit) to the tractor ABS ECU. Do not use the F65A1 or F64A1 circuits for powering items such as: • large inductive or capacitive loads such as electric motors or continuously-activated solenoids • add-on equipment which uses a type of Power Line Carrier (PLC) communication which is not compatible with the PLC4TRUCK signal |

| Doing so may affect the PLC4TRUCK signal, resulting in a loss of trailer ABS malfunction indication. |

| Likewise, do not use the F65A1 or F54A1 circuits for powering sensitive communication |

| If you will be connecting to a trailer equipped with the PLC4TRUCK system (basically, any air-braked trailer manufactured after March, 2001), it will be the user's responsibility to ensure that any add-on electrical equipment does not interfere with the trailer ABS malfunction circuit function. |

Ground Circuit (X03EA2)

This ground circuit should be used as much as possible for all body builder ground needs. It connects to a ground stud on the vehicle firewall which is a central ground point for all vehicle electrical loads. Note the maximum current capacity of the circuit (dictated by the 6.0mm2 conductor size) of 30A.

Reverse Circuit (F63H2)

This is a 10A (max) circuit, live when the transmission is placed into REVERSE gear. It shares a relay (RLY14) and fusing (F63) with the lift-axle logic: when the transmission is not in reverse, the lift axles are allowed to operate; when the transmission is in reverse, circuit F63H2 receives power.

Note: OVERLOADING CIRCUIT F63H2 (and causing F63 to blow) WILL PREVENT PROPER OPERATION OF THE LIFTAXLES

Allison Controlled Relays

(NADA1/NACA1/NABA1 and NAEA1/NAFA1/NAGA1) - Allison Transmission Only

Two relays are provided which are controlled by the Allison Transmission circuits N145A1 and N130A1. See the diagram below.

W3127852

Refer to either Allison Transmission documentation, or the Body Builder Transmission service bulletins, for details on the exact functions of these circuits, as they differ depending upon which vocational package was chosen.

Stalk PTO Engine Speed INC/DEC (MAKA1, MALA1)

These circuits are provided for "remote" adjustment of the engine speed while operating in "stalk PTO" mode. They are connected to relays which operate in parallel with the "SET+" and “SET-" stalk switches, and will allow trimming of the PTO engine speed just as if the in-cab controls were used, except for the added requirement that the vehicle's park brake must be set in order to use these "remote" control circuits.

As with the in-cab stalk PTO mode of operation, the Cruise Control On/Off switch must remain "on". The 'base' PTO set speed should be selected before exiting the cab.

These circuits are usable on both VOLVO and Cummins engines (VNL only), with the same mode of operation that each engine has concerning the in-cab "stalk PTO" operation. Refer to the "Stalk PTO" topic in the "PTO Functions" section of this document.

PTO1 Input/Enable and Output

(F34E3, F34C3) - VOLVO Engine Only

These circuits provide access to the single PTO function of the VECU, and are usable with the VOLVO engine only. If more than one PTO function is required for your application with the VOLVO engine, a body builder module (BBM) ECU will be required - refer to the section on the ELCE-CK prep package.

For a complete description of the PTO1 Input/Enable and Output functions of the VECU, please refer to the "VECU Functions" section of this document.

For all wired-PTO functions with the Cummins engines, it will be necessary to wire directly to the Engine ECU. Refer to the section on the ELCE-EK prep package for available pre-wired circuits, and also to Cummins Engine Company documentation for PTO operation with these engines.

Notes:

1. ELCE-PK is standard equipment on all VHDs (truck and tractor), unless specified otherwise.

2. ELCE-PK is available with all engines.

3. ELCE-PK is available with all transmissions; additional content is included when Allison transmission is specified.

4. The wiring for the PTO Relay (RLY07), PTO DASH SWITCH, and "PTO" fusing are present in every VHD; the components themselves are only installed when one of the available PTO-prep options are ordered.

5. The function of all Allison Transmission circuits (Axxx) will depend on the chosen Vocational Package; REFER TO ALLISON DOCUMENTATION FOR DETAILS.

VHD Body Builder Wiring

W3119185

“Complete” Prep Kit; Including BBM ECU; ELCE-CK (Sales Code: L3-C1)

The "complete" prep kit adds a body builder module (BBM) electronic control unit (ECU) and associated wiring to the standard "basic" prep kit. The ELCE-CK kit is only available with a VOLVO engine.

The following tables list the pinout and mating connector information for the 16-way body builder connectors which are part of the ELCE-CK package, located on the cab floor between the seats.

Description of Circuits Included in ELCE-CK ("Complete" Prep Kit)

In addition to all the circuits listed above in the ELCE-PK package, the ELCE-CK package adds the body builder module (BBM) electronic control unit (ECU), together with the following circuits brought out to two additional connectors located between the seats (same location as -PK package).

Connector #3

Connector # BB-EK

Type: 16-way, unsealed Packard GT 150-series (female housing w/ female terminals)

Location: Between driver and passenger seat

Present: Always present with ELCE-CK option (sales code L3-C1)

| Pin | Circuit Gen 2 2018 | Circuit Gen 1 Pre 2018 | Description | Notes |

| A | X03DB16 | X03EA21 | Ground return for all BBM-connected Inputs | |

| B | MB5A3 | MB5A3 | +V Power for BBM-connected Switches | Limit to -10 switches per +V output |

| C | MB19A1 | MB19A1 | +V Power for BBM-connected Switches | Limit to -10 switches per +V output |

| D | MA18A2 | MA18A2 | PTO2 Input/Enable | All PTO inputs are Active High; See VECU (ELCE-PK) for PTO1 Input/Enable |

| E | MA19A1 | MA19A1 | PTO3 Input/Enable | |

| F | MA20A1 | MA20A1 | PTO4 Input/Enable | |

| G | MA4A1 | MA4A1 | PTO1 Engine Speed Control Input | Active High Inputs |

| H | MB21A1 | MB21A1 | PTO2 Engine Speed Control Input | |

| J | MA3A1 | MA3A1 | PTO3 Engine Speed Control Input | |

| K | MA5A1 | MA5A1 | PTO4 Engine Speed Control Input | |

| L | MB2A1 | MB2A1 | PTO2 Output | Active Low Outputs; limit to 1 Amp per output. See VECU (ELCE-PK) for PTO1 Input/Enable |

| M | MB3A1 | MB3A1 | PTO3 Output | |

| N | MB4A1 | MB4A1 | PTO4 Output | |

| P | MA1A1 | MA1A1 | Remote PTO Engine Speed DECrement | Active High Inputs; act on PTO2-4 only |

| R | MA2A1 | MA2A1 | Remote PTO Engine Speed INCrement | |

| S | F44BS | N/A | Hood Position Switch | Optional |

Connector #4

Connector # BB-EK

Type: 16-way, unsealed Packard GT 150-series (male housing w/ male terminals)

Location: Between driver and passenger seat

Present: Always present with ELCE-CK option (sales code L3-C1)

| Pin | Circuit Gen 2 2018 | Circuit Gen 1 Pre 2018 | Description | Notes |

| A | MA6A1 | MA6A1 | Engine Shutdown #1 Input (See Note 1) | Normally Open (N.O.) Switch to +V |

| B | MA27A1 | MA27A1 | Engine Shutdown #2 Input (See Note 1) | Normally Closed (N.C.) Switch to Ground |

| C | MA7A1 | MA7A1 | Forced Idle/Throttle Interlock Input | Active High Input |

| D | MA17A1 | MA17A1 | Engine Speed Limit Input | Active High Input |

| E | MA25A1 | MA25A1 | Engine Torque Limit Input | Active Low Input |

| F | MA26A1 | MA26A1 | Road Speed Limit Input | Active Low Input |

| G | MA24A1 | MA24A1 | PTO Neutral Interlock Input | Active Low Input |

| H | MA28A1 | MA28A1 | PTO Low Split Gear Interlock Input | Active Low Input |

| J | MA29A1 | MA29A1 | Split Shaft PTO Input | Active High Input |

| K | MB12A1 | MB12A1 | Remote Throttle Enable Input | Active Low Input; See Note 2 and 3 |

| L | MB10A1 | MB10A1 | Remote Throttle V-Ref (5V) Output |

See Note 2 and Note 3. Use twisted-trio wiring for these three circuits |

| M | MB9A1 | MB9A1 | Remote Throttle Sensor/Signal Input | |

| N | MB22A1 | MB22A1 | Remote Throttle Ground Reference | |

| P | MB28A1 | MB28A1 | Road Speed Output ("C3" Output) | Active High Output |

| R | MB16A1 | MB16A1 | System Warning Output | Active Low Output |

| S | MB18A1 | MB18A1 | Databus Triggered Output | Active Low Output |

Notes:

1. Engine Shutdown Input #1 is always enabled. Do not install a switch at that position if function is not required. Engine Shutdown Input #2 must be enabled in software, and once enabled will shutdown the engine unless ground is present at that input.

2. For stationary 2nd Throttle use, it is recommended to add a redundant Park Brake pressure switch in series with the Remote Throttle Enable Input (see schematic). This will allow remote throttle only while the park brake is set. DO NOT tie into the factory-installed Park Brake pressure switch for this purpose.

3. For non-stationary 2nd Throttle use, an Accelerator Pedal with Idle Validation Switch (IVS) is required. Circuits for the IVS are not brought out to Body Builder Connector #4. Refer to the BBM ECU section of this document for details on the circuitry needed for a 2nd driving position.

Connector/Mating Part Information

All part numbers shown are Delphi / Packard, unless otherwise noted.

| Connector/Item | Supplied on vehicle | Mate required to plug in to Vehicle |

| Connector #3 | Connector #3 Packard 150-GT series (unsealed), 16-way; Female housing & Ter- minals Packard 150-GT series (unsealed), 16-way; Male housing & Terminals |

Packard 150-GT series (unsealed), 16- way; Male housing & Terminals |

| Housing Assembly | Packard PN 15332177 VOLVO PN 20481359 |

Packard PN 15332182 VOLVO PN 20481361 |

| Terminals | Packard 12191812 (0.75 ~ 1.00 mm²) | Packard 15304702 (0.75 ~ 1.00 mm²) Packard 15304701 (0.35 ~ 0.50 mm²) |

| Connector #4 | Packard 150-GT series (unsealed), 16- way; Male housing & Terminals |

Packard 150-GT series (unsealed), 16- way; Female housing & Terminals |

| Housing Assembly | Packard PN 15332182 VOLVO PN 20481361 |

Packard PN 15332177 VOLVO PN 20481359 |

| Terminals | Packard 15304702 (0.75 ~ 1.00 mm²) | Packard 12191812 (0.75 ~ 1.00 mm²) Packard 12191811 (0.35 ~ 0.50 mm²) |

Notes:

1. ELCE-CK is standard equipment on VHD trucks; optional on VHD tractors.

2. ELCE-CK includes all contents of the 'basic' prep (ELCE-PK).

3. ELCE-CK is only available with VOLVO engines. 4. ELCE-CK is available with all transmissions.